In high-temperature, dust-prone environments like Qatar, the wrong belt can quietly drain productivity—through micro-slips, heat glazing, and unexpected downtime. The right specification reduces energy use, extends asset life, and lowers total cost of ownership (TCO).

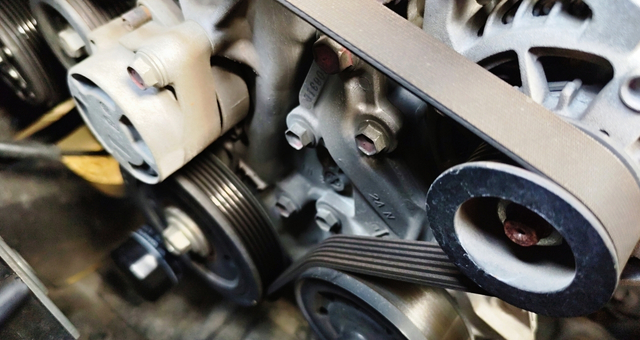

Belt families at a glance

- Timing belts (HTD/GT series): Synchronous, no slip, ideal for precision.

- Classic & narrow V-belts: Robust, easy to install, good for general drives.

- Multi-rib (Poly-V): High speed, compact drives, low vibration.

- Flat belts: Low noise, good for light conveyors and textile lines.

Step-by-step selection

- Confirm duty & torque: kW/HP, rpm, ratio, service factor.

- Check environment: temperature, dust, oil, chemicals, wash-downs.

- Pick profile/material: e.g., HTD 8M for torque; oil/heat-resistant compounds for refineries.

- Size correctly: center distance, pulley diameters, wrap angle; avoid under-tensioning.

- Choose branded quality: genuine, dimensionally accurate belts deliver longer life.

- Plan spares: stock critical sizes, matched sets, and tensioners.

Common failure signs (and fixes)

- Sidewall glazing: heat or low tension → align, set tension, improve ventilation.

- Cracking/edge fray: misalignment or tight pulleys → re-align, respect bend radius.

- Tooth shear (timing): shock loads → wider/stronger belt, torque reserve.

- Squeal/slip: oil or low tension → clean pulleys, replace, retension.

Installation & tensioning checklist

- Clean pulleys; never pry belts on.

- Use a tension gauge; re-check after 24–48 hours.

- Laser/straightedge alignment; verify runout.

- Fit guards; record install data.

Maintenance intervals

- Weekly: visual/noise check.

- Monthly: tension & temperature; clean-downs.

- Quarterly: pulley wear, alignment audit, replace sets together.

TCO best practices

Specify energy-efficient profiles, correct grooves/pulley hardness, and maintain a lean spares matrix by line criticality.

CTA: Need help spec-ing or auditing your drives? Contact YAFWAY at info@yafway.com or +974 5041 6444 for genuine high-performance belts and on-site support.