Matching conveyor to application

-

Rubber belts: mining, quarry, cement—abrasion/heat-resistant compounds.

-

Metal/wire-mesh: ovens, foundries—handles heat, sharp edges, heavy loads.

-

Food-grade PU/PVC: hygienic, FDA/EU compliant, easy sanitation.

Eight specification decisions that matter

-

Material characteristics: bulk density, temperature, abrasiveness, oil.

-

Capacity & speed: tph/cph targets, surge factors, growth margin.

-

Trajectory & layout: elevation, curves, transfer points, guarding.

-

Belt selection: tensile class, cover thickness, chevron for incline.

-

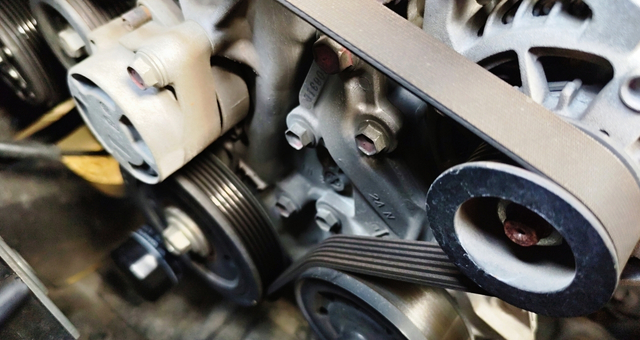

Drive & control: motor type, gearbox ratio, VFD for soft-start/speed trim.

-

Idlers & pulleys: CEMA/ISO class, sealing for dust/humidity.

-

Sanitary requirements: CIP, quick-release parts, stainless frames.

-

Maintainability: splice method, fasteners, take-up, access platforms.

Installation essentials

-

Pre-align structure; torque fasteners to spec.

-

Drive pulley lagging; precise tracking at start-up.

-

Integrate safety sensors (zero-speed, mis-tracking, pull-cord E-stops).

-

Commission with baseline vibration/temperature readings.

Maintenance playbook

-

Daily: clean spillage, check tracking/guards.

-

Weekly: inspect idlers for noise, splice condition.

-

Monthly: verify tension, pulley wear, scraper blades.

-

Quarterly: laser alignment, oil sampling, lagging condition.

KPIs to watch

MTBF, specific energy (kWh/ton), carryback %, cleanup hours, planned vs unplanned downtime.

Food & pharma notes

Use stainless components, avoid debris-collecting horizontals, specify blue belts for contaminant contrast, document sanitation cycles.

CTA: Planning an expansion or retrofit? YAFWAY designs, supplies, installs, and maintains complete conveyor systems. Email info@yafway.com to book a site surve